Professional welding equipment produced at the PSTM LTD is designed for critical welding operations and provides realization of all current known methods of electric arc welding. PSTM LTD produces industrial welding equipment for manual and mechanized electric arc welding of steels, aluminum and alloys.

- Welding sources for MIG/MAG welding

- Welding sources for TIG welding

- Wire feeders

- Liquid cooling units

- Remote control

- Digital torches

- Cable packages

- Carts

- etc.

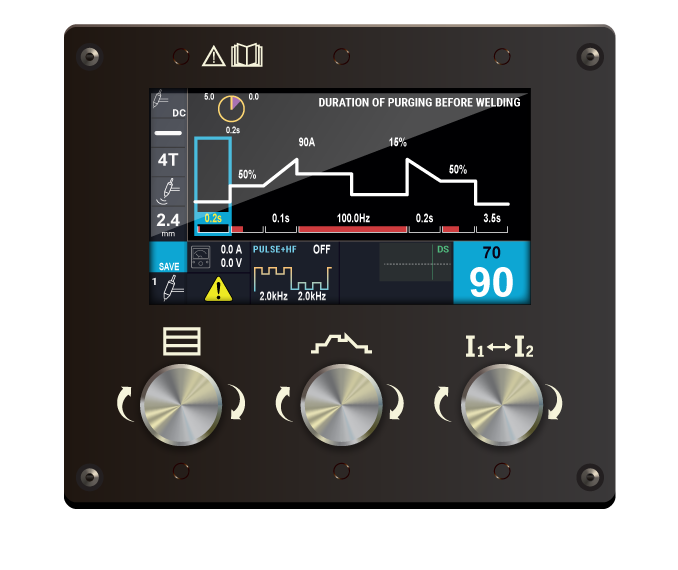

TIG — argon-arc welding

- Welding current from 300 up to 1000 A

- 100% PV at 40 °C

- 96% efficiency

- Welding at DC or DC and AC currents

- 39 memory cells in the ROM

- Liquid cooling unit

- Gas flow control system

- WeldWeb ® network control system

- Control modes: 2T / 4T / 4T Special

- Modulation: Pulse / HF / Pulse + HF

- Seam type: Nonstop / Spot / Interval

- Rod Flux Coating: Acid, Basic, Cellulosic, Rutile

- AC waveform: Sine / Triangle / Rectangle / Trapezoid / Auto mode

- Functions: Hot Start, Arc Force

- Lift Arc – contact arc ignition

- HF – smooth high-frequency ignition

- TIG AC Auto – automatic frequency adjustment

MIG — semi-automatic welding

- Welding current 300 / 350 / 400 / 450 / 500 / 550 A, above 550 A on request

- Access restriction system

- PV 100% at 40 °C

- 96% efficiency

- 100 cells in ROM

- Support for digital torches

- Liquid cooling unit

- Gas flow control system

- WeldWeb ® network control system

- Control modes: 2T / 4T

- Synergy control: on /off / adjustment

- Wire feed: synergistically / independently

- Hot Start

- Crater welding