PSTM LTD produces welding equipment under the trademarks:

EVOSPARK, ROSWELD, TENA and STEELARC.

Serial welding equipment

EVOMIG, ROSWELD MIG,TENA MIG, STEELARC EVOMIG – power sources for semi-automatic welding

EVOTIG, ROSWELD TIG, TENA TIG, STEELARC EVOTIG – power sources for argon-arc welding with non-consumable electrode

Serial welding equipment for manual and mechanized electric arc welding – industrial equipment designed for carrying out critical welding works and providing implementation of all currently known methods of electric arc welding, which is used in:

- heavy machine building,

- automotive industry,

- transport machine building,

- shipbuilding,

- fabrication of metal structures,

- power industry and other industries.

To custom-made

To custom-made universal high-power current sources for various industries. They demand in:

- metallurgy for steel arc furnaces,

- for powerful plasmatrons in waste processing plants,

- for plasma cutting machines,

- for the production of nanomaterials, etc.

Architecture and characteristics of power supplies

The basic principle of construction of current sources produced by PSTM LTD is the separation of the power part and digital control.

The power part has a modular architecture – all sources are built from parallel connected unified power modules, each of which is a separate autonomous high-frequency inverter with the following characteristics:

- 3×380 V ± 25% power supply

- Frequency 150 kHz

- 96% efficiency

- SP 100% (40°C, 300 A, 45 V)

- Parallel connection

- Output power 5-8 kW

- Dimensions 20×20×21 sm

- Weight 6,7 kg

- Adaptive air cooling control

In the current source, the modules are connected in parallel, the power of the source can be easily increased up to 40 kA.

Digital welding equipment produced by PSTM LTD differ from “conditionally digital” sources by the microprocessor in the arc welding circuit, which provides real-time adjustment output VAC (volt-ampere characteristics).

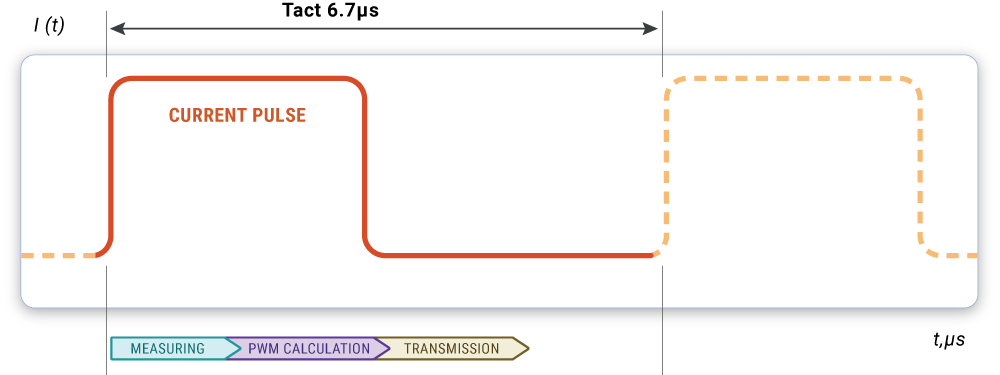

The inverter digital control system in each control cycle (6.5 µsec) calculates the value of the VAС parameters based on the measured welding parameters and the specified work program.

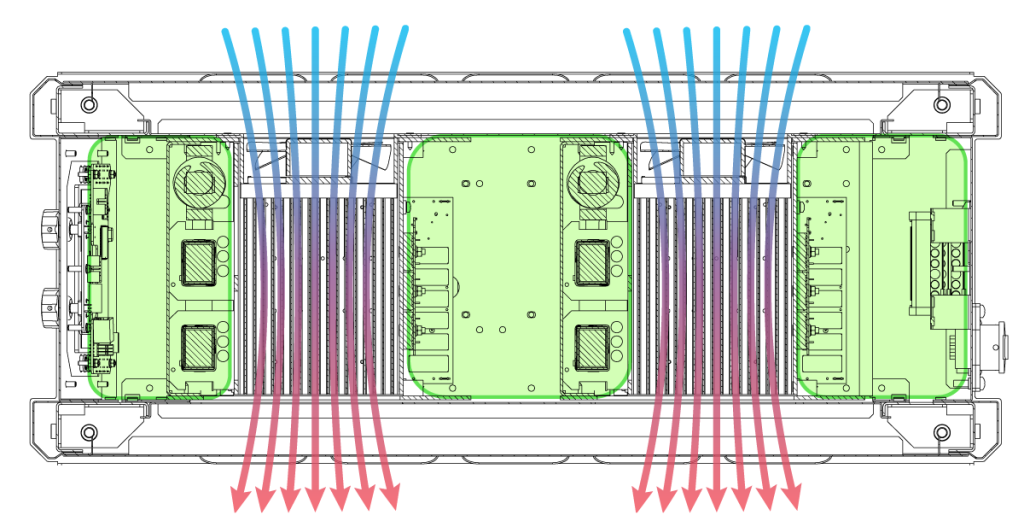

Cooling based on the “dust pipe” principle

Sensitive electronic components are isolated from the cooling air flow that passes through the machine body and may contain large amounts of dust..

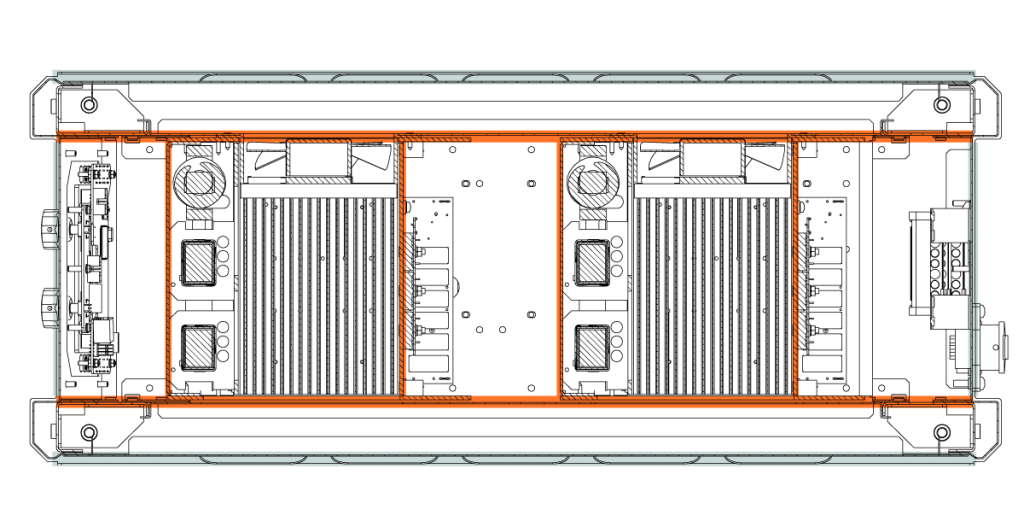

Double body made of rigid frame and cladding panels

Structurally, the device consists of a rigid frame on which the components are mounted, and lightweight panels. This ensures the strength and lightness of the entire structure.

What makes PSTM ltd power supplies so convenient

For a welder:

- Color graphic display

- Menu with pop-up prompts

- Synergistic control with consideration of materials used in the shipbuilding industry

- Saving of customized modes

- Clear cyclogram showing all parts of the welding process

- Switching from torch

For a technologist:

- Special welding modes to reduce the time for process operations

- No spattering

- Operation in difficult contaminated conditions, at high temperature and humidity (IP34)

- Welding production management system within the INDUSTRY 4.0 concept

- Design features that reduce machine downtime

- Expansion of the technological capabilities of the equipment only through software upgrades

Multifunctionality is provided by software and does not entail the disadvantages that usually accompany the versatility of technology.

The apparatuses are equipped with:

- digital control,

- ranking of access to settings,

- monitoring and documentation of the provided welding parameters, including at a remote workplace.

Modular design of the power part has no analogues in the world and provides high dust and moisture protection of electronics, maintainability and reliability of operation. The equipment is reliable and economical in operation.

- IP 34

- SP 100%

- EFFICIENCY 96%

- Warranty period of 36 months