Studying the specifics of using welding equipment at various enterprises and in the production of various works, specialists of PSTM LTD plant can take into account the requirements and develop special characteristics of welding equipment. That is, to carry out adaptation and customization both according to the customer’s technical task and independently.

Examples of adaptations:

For shipbuiding

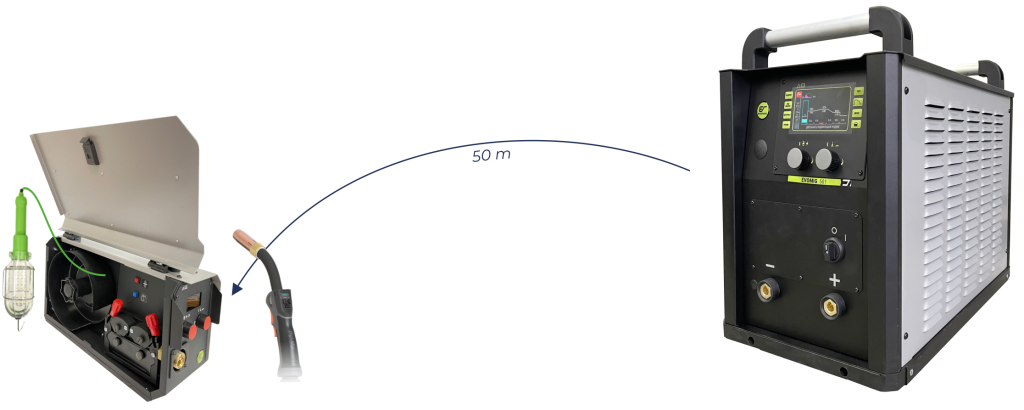

EVOMIG 350 or EVOMIG 500 semi-automatic welding machine with compact wire feeder compact wire feeder UPP-200K with the possibility of switching programs from the digital torch.

UPP-200K:

- compact, weighs 9.5 kg

- adapted for work on an open slipway at sub-zero temperatures

- has a library of materials for shipbuilding

- has a socket for connecting a portable lighting device and a gas heater

- is equipped with an illuminated internal volume.

For assemlby work

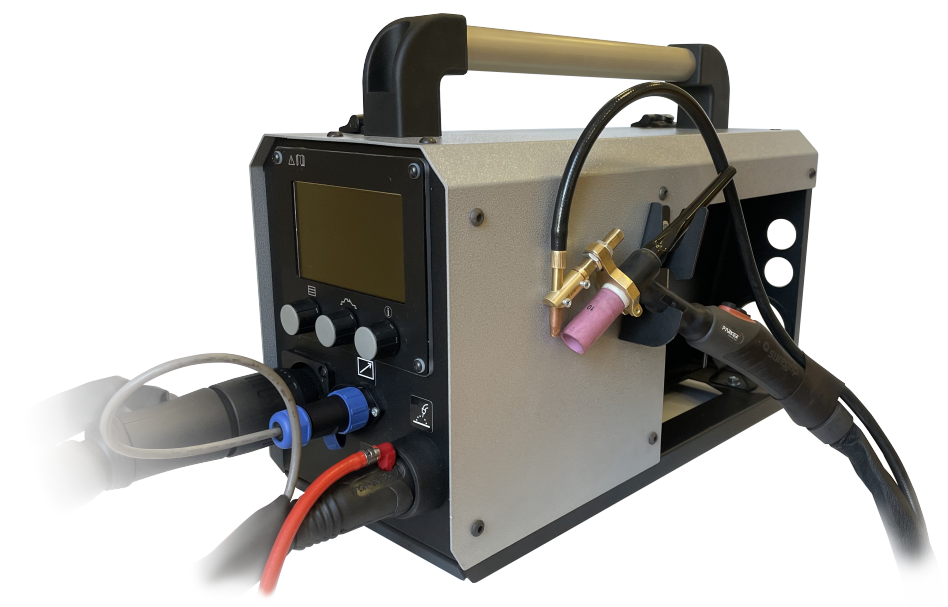

EVOTIG 200 P DC is a portable welding machine DC argon-arc welding machine designed especially for thermal installation work.

- TIG and MMA versatility

- Low weight = less than 10 kg

- High efficiency = 90%

- Input voltage range 220 ± 25%

- Shockproof metal housing

- High-frequency arc modulation (focusing) function, which avoids non-melting defects in the root seam

- Non-contact ignition for easy arc initiation and prevention of tungsten inclusions in the weld metal

- Pulse mode for welding in vertical position.

For food industry

EVOTIG 200 P DC is a portable welding machine DC argon-arc welding machine designed especially for thermal installation work.

- Maximum control of the welding wire speed is achieved with the 4 roller PPC and optical motor control sensor.

- The digital speed control ensures extreme precision in the welding process and excellent welding properties.

- etc.